Rope MRT INTRON

Wire ropes are vital components across industries, bearing heavy loads and securing critical structures. However, hidden within their robust exteriors lies a silent danger – internal deterioration. Traditional visual inspections, though valuable, often miss these issues due to various factors, especially in multi-strand, rotation-resistant ropes. INTRON Magnetic Rope Testing (MRT) steps in as the solution for safety, compliance, and operational reliability.

The Hidden Risk: Internal Deterioration

Internal degradation is a leading cause of unexpected wire rope failures, posing threats like injury, equipment damage, legal liabilities, and financial losses. Detecting and mitigating this risk goes beyond regulation; it's essential for personnel safety and asset protection.

A Data-Driven Imperative

INTRON MRT offers invaluable insights into wire rope condition, including residual breaking strength assessment. With this data, organizations can make informed decisions about safe operation and maintenance.

In summary, INTRON MRT is not just a regulatory requirement; it's a strategic investment in safety and reliability. By uncovering hidden threats within wire ropes, INTRON empowers organizations to prevent accidents, protect assets, maintain reputations, and ensure long-term success.

Services

Acumen Safety's specialized MRT team is equipped with the latest INTRON MRT Equipment, capable of inspecting ropes ranging from 6mm to 175mm in diameter. We offer comprehensive MRT services for various applications, ensuring the safety and reliability of critical components around the world with multinationality and multi discipline team.

With Intros MRT Inspection data it enables Acumen Safety to assess the residual breaking strength of steel wire with rope strength software.

Our MRT services encompass:

MRT of Wire Ropes in Cranes and Winches: Precise inspections to guarantee the integrity of crucial lifting equipment.

Acumen Safety offers a comprehensive rope inspection ranging from 6 mm to 175mm, covering various rope types used in diverse applications onshore and offshore. From standard stranded ropes to intricate half-locked and full-locked designs, MRT ensures the integrity of each construction. It also effectively assesses plastic-coated and plastic valley-filled ropes, providing a complete evaluation regardless of the material or core type—whether it's bright or galvanized wire, or features a fiber or steel core. INTRON MRT's versatility guarantees a thorough examination, contributing to safety and reliability in a wide range of industries and applications.

With Intron MRT is not just about measuring the loss of metallic area (LMA) caused by factors like corrosion, abrasion, or wear. It goes beyond by revealing local flaws (LF) that can hide internal and external broken wires, pitting corrosion, cross-nicking, welding spots, and more.

This level of detail enables the asset owner to make informed decisions about maintenance and safety, ensuring the integrity of your operations.

Flare Stack Inspection with Climber: Overcoming Challenges for Safety

Inspecting static wire ropes within flare stacks has historically posed unique challenges, primarily due to their challenging location and extreme temperatures. However, Acumen Safety rises to this challenge with our innovative self-driven climber, coupled with INTRON's magnetic head technology. Together, they enable precise assessments of rope condition, ensuring the reliability and safety of critical guy wires. With this cutting-edge solution, we overcome even the most formidable conditions to deliver accurate results and maintain the highest standards of safety.

Wire Rope Inspection of Cable Cars

Safeguarding Public Safety: Wire Rope Inspections for Cable Cars

Wire ropes in cable cars have a direct impact on public safety. Given recent accidents and incidents worldwide, it is imperative that these ropes undergo periodic assessments to ensure their reliability. Acumen Safety specializes in conducting thorough inspections of these critical assets to guarantee safety and serviceability. Our commitment to safeguarding public safety is unwavering, and we take every measure to ensure the integrity of cable car wire ropes.

Zip Lines and Wire Ropes in Amusement Rides.

Ensuring Thrills with Safety: Zip Lines and Amusement Ride Wire Rope Inspections

Zip lines and wire ropes in amusement rides are all about delivering excitement, but safety should never take a backseat. The importance of periodic inspections to ensure safe and thrilling experiences. Acumen Safety steps in as your trusted partner, conducting meticulous inspections to guarantee the safety and serviceability of these high-adrenaline assets with state of the art self driven climbers with INTROS magnetic head. We are committed to upholding the highest safety standards so that thrill-seekers can enjoy their adventures with peace of mind.

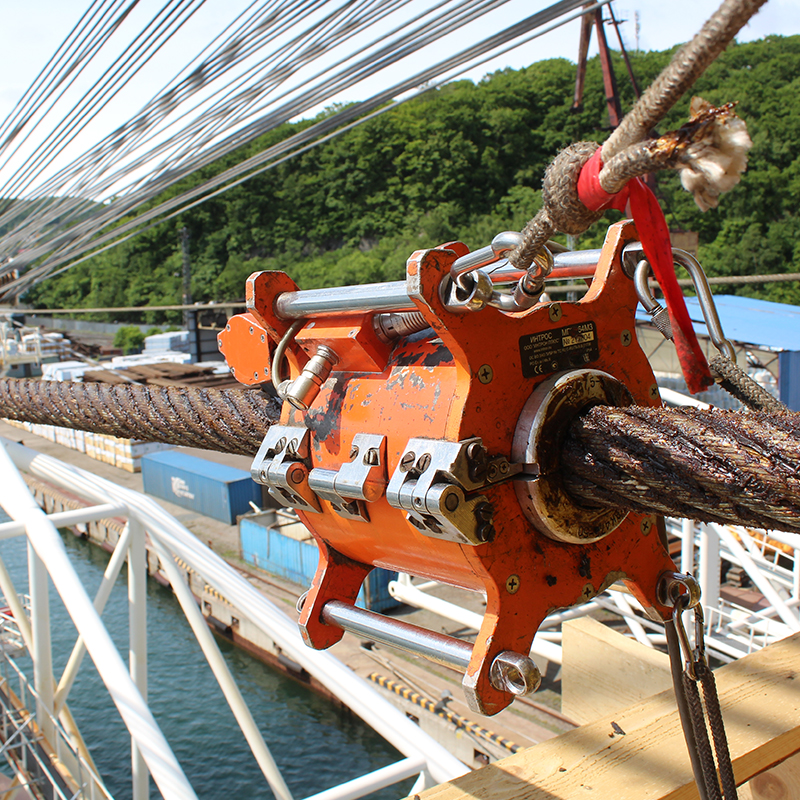

Bridge Stay Wire Inspection

Elevating Bridge Safety: MRT in Stay Wire Inspections

When it comes to bridges, the integrity of stay wires is paramount. Magnetic Rope Testing (MRT) plays a crucial role in enhancing bridge safety. Acumen Safety harnesses the power of MRT technology to conduct precise inspections of stay wires. By penetrating the core of these critical components, we ensure their reliability and structural soundness. With MRT, we provide invaluable data to maintain the safety and longevity of bridges, safeguarding the infrastructure that connects communities.

INTRON

Being the world’s first company to develop state-of-the-art NDT machines, INTRON has been a market Leader and has advanced a long way since its inception in the early 80s. INTRON utilizes patented technology for its Product development. These products are not only patented but also certified and registered with the relevant authorities, ensuring their quality and compliance with numerous International regulations like ASTM E1571-11, ISO 4309, EN 12927, IMCA LR 004,IMCA HSSE 023, IMCA M 197 Rev.1.

INTOS Units for Wire Rope MRT have a reputation of being Rugged, Reliable and Accurate in the toughest of environments. Customised R&D products catering to various industries and applications.

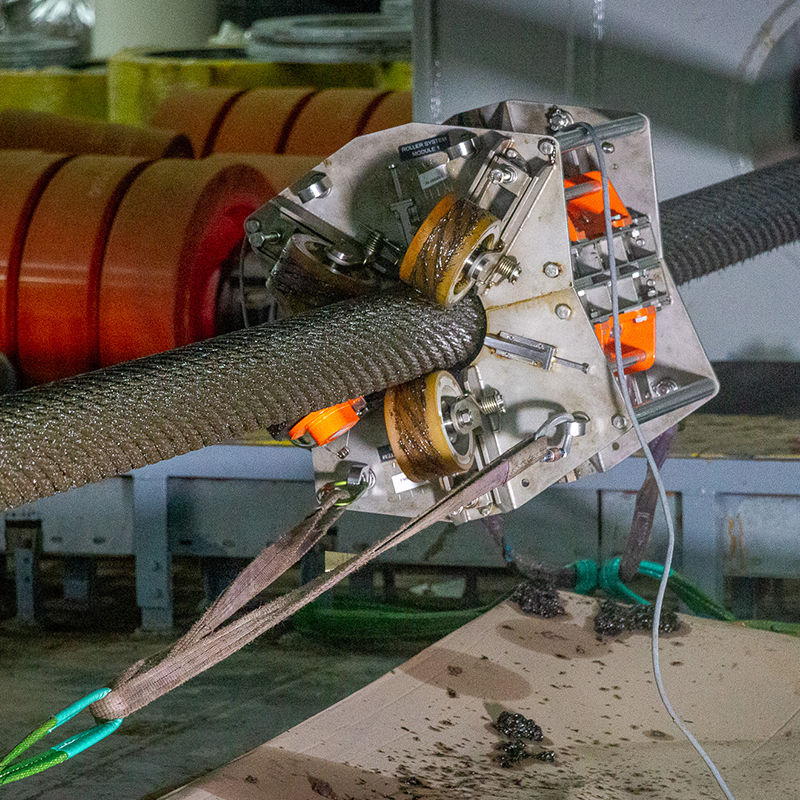

INTRON MRT: Precision in Wire Rope Inspection

The heart of INTRON's Magnetic Rope Testing (MRT) system lies in its principle of operation – the magnetic flux leakage (MFL) method. This method detects anomalies by identifying disruptions in the normal flux patterns within ferrous materials that are saturated by a magnetic field. Commonly referred to as Magnetic Rope Testing (MRT), this inspection method is a game-changer.

INTRON's capabilities cover a wide range of rope diameters, from 6mm to 175mm, making it a versatile tool for inspections in various industries. Whether it's mines, cranes, elevators, ropeways, bridges, or overhead transmission lines, INTRON's dual-function instrument offers unmatched capabilities.

Dual-Function Instrument

INTRON is not just about measuring the loss of metallic area (LMA) caused by factors like corrosion, abrasion, or wear. It goes beyond by revealing local flaws (LF) that can hide internal and external broken wires, pitting corrosion, cross-nicking, welding spots, and more. INTRON is well-suited for inspecting a wide range of rope types, including stranded, spiral, half-locked, full-locked, plastic-coated, or plastic valley-filled ropes made from bright and galvanized wire, with either fiber or steel cores.

Magnetization for Precision

The MRT system is designed to establish a magnetic circuit that magnetizes the metallic cross-section of the rope up to its saturation level. To put this in context, according to EN 12927:2019, the magnetizing unit must generate a magnetic flux density between 1.9 and 2.3 Tesla in a rope. This strong and uniform magnetization of the rope's cross-section is essential to achieve a high defect detection rate throughout the rope cross-section, especially for wire breaks within the core.

Accreditation and Certification

INTRON's performance aligns with international standards, including ASTM E1571, ISO 4309, EN 12927:2019, IMCA LR 004, IMCA HSSE 023, and IMCA M 197 Rev 1.

Our Products and After-Sales Service

Explore our range of products, including Magnetic Rope Testing. When it comes to after-sales service, Acumen Safety stands ready to assist. Our Technicians are highly trained and INTRON PLUS-accredited.

Intros Auto

INTROS-AUTO is specifically engineered for conducting non-destructive inspections on steel wire ropes, offering automated data interpretation. The results are presented in a "traffic light" mode, where a green light signals that the rope can continue to be used, a yellow light indicates a certain level of rope deterioration (adjustable) – applicable to both LMA and LF, and a red light warns against further use of the rope.

The assessment of the rope's actual condition relies on several criteria, including the number of broken wires within a specific rope length, the percentage of metallic cross-sectional area loss, and the rate of rope degradation. All inspection data are readily accessible for manual interpretation by an inspector at any time.

Furthermore, INTROS-AUTO can be seamlessly connected to an external computer to facilitate continuous wire rope monitoring.

Intros Auto: Real-Time Rope Condition Monitoring

Intros Auto provides on-demand insights into your rope's condition. Installed directly on the machine, it continuously updates information about the rope's status, ensuring asset owners have real-time awareness of its condition at all times. Stay informed and proactive with Intros Auto.

After Sales: Repair, Verification & Spares.

We provide sales, service, repair, and verification for the full range of INTRON equipment at our UAE Service Centre. As users of the equipment ourselves, we offer unparalleled technical advice, ensuring that you get the most from your equipment and accurate interpretation of results.

Acumen Safety – Together, We Refine Expertise and Excellence.

Contact us to discover how INTRON MRT can elevate safety and reliability in your operations while adhering to the highest international standards.